Displaying items by tag: WEDM

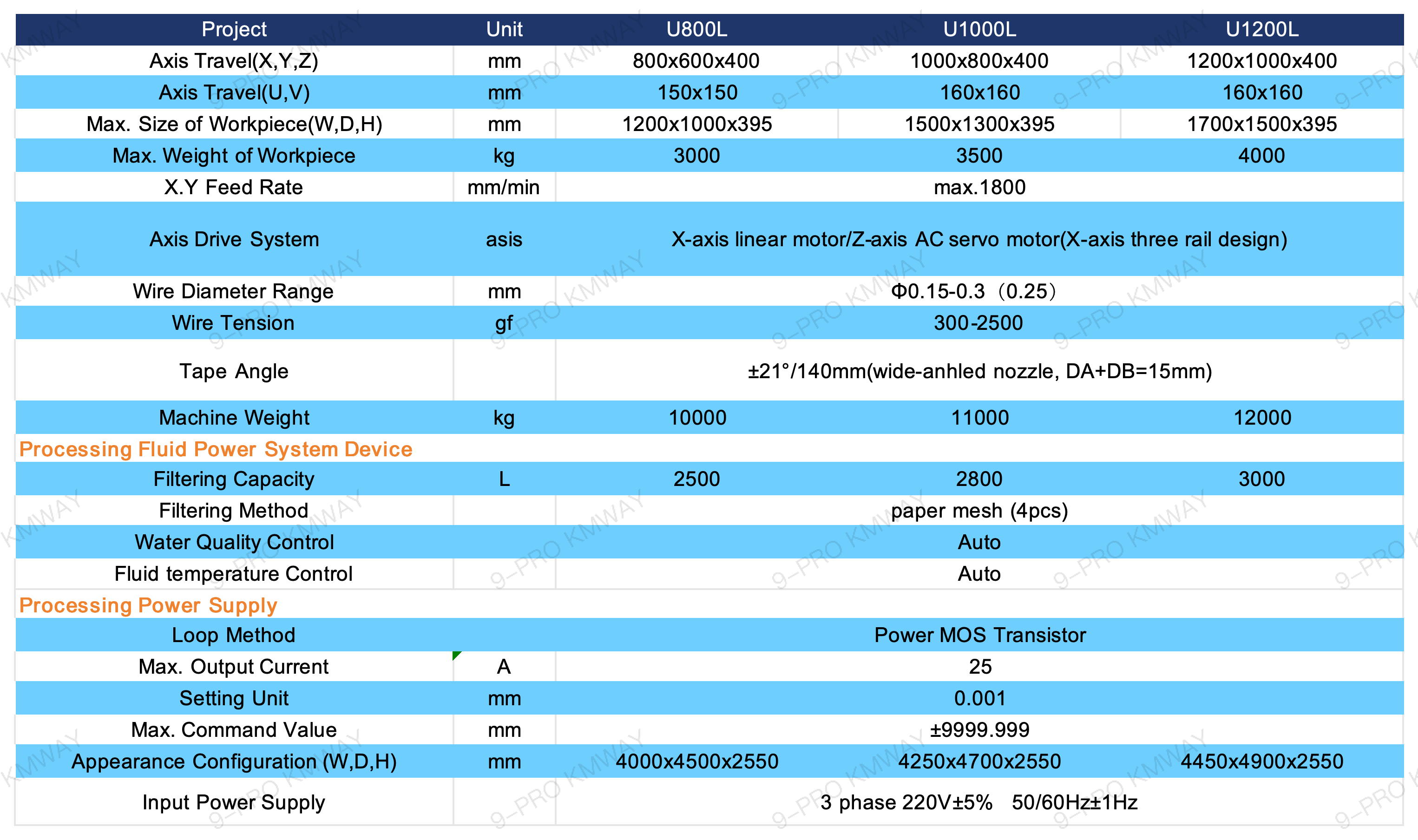

U800L / U1000L / U1200L

1. Kmway machines combine the advantages of Taiwanese machines and Japanese machines, mainly in synchronization with Chmer's eighth-generation discharge controller, with consistent finish, precision and efficiency; the AWT system has learned the advantages of Japanese machines and has been updated to the third generation, with a conservative success rate of 95%; including our 3 vertical motors, which are safer and more efficient, less prone to breakdown, and lower maintenance costs.

2. Our service and after-sales team, our technicians can help customers answer questions online at any time. Although the normal working hours are from 8 am to 8 pm China time, when customers really have problems, no matter what time it is, we will try our best to help customers solve them quickly. Including our after-sales team, during dealer training, our after-sales engineers will list the problems and solutions that customers often encounter during use based on their rich experience to help dealers improve the quality of after-sales service.

3. Although Kmway is a new company, we have a strong R&D team (located in Hangzhou, Zhejiang, China). We pay great attention to customer feedback. As long as the customer raises a question, we will carefully study and give feedback, and have been studying how to improve the efficiency of our machines. Now we have made the U series. There are few brands in the market that can make such a long-stroke machine and our price must be the most cost-effective, which can give customers more choices and there will be no shortage of supply.

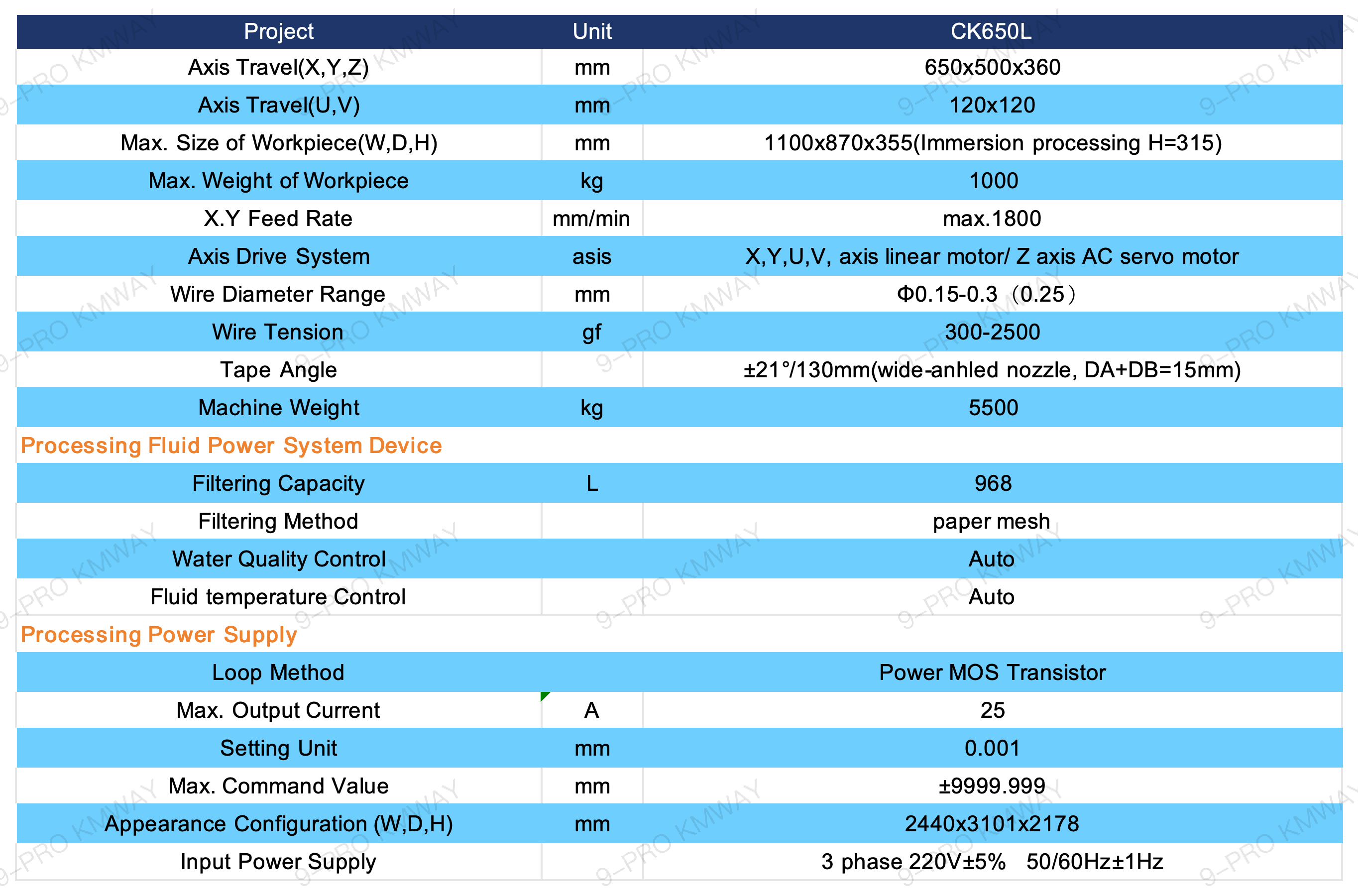

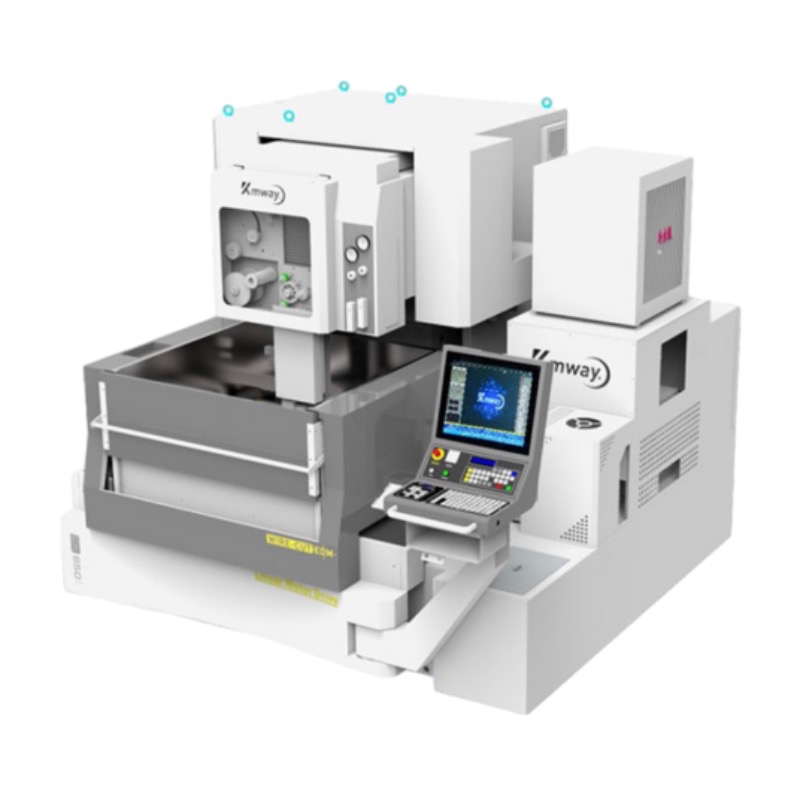

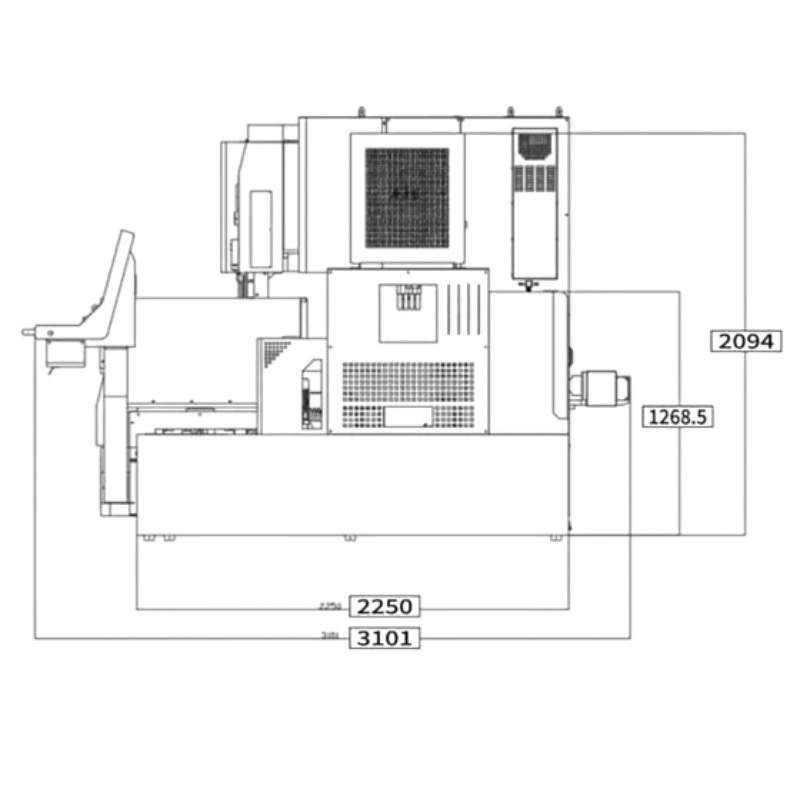

CK650L

CK series comes standard with AWT system

1. Kmway machines combine the advantages of Taiwanese machines and Japanese machines, mainly in synchronization with Chmer's eighth-generation discharge controller, with consistent finish, precision and efficiency; the AWT system has learned the advantages of Japanese machines and has been updated to the third generation, with a conservative success rate of 95%; including our 3 vertical motors, which are safer and more efficient, less prone to breakdown, and lower maintenance costs.

2. Our service and after-sales team, our technicians can help customers answer questions online at any time. Although the normal working hours are from 8 am to 8 pm China time, when customers really have problems, no matter what time it is, we will try our best to help customers solve them quickly. Including our after-sales team, during dealer training, our after-sales engineers will list the problems and solutions that customers often encounter during use based on their rich experience to help dealers improve the quality of after-sales service.

3. Although Kmway is a new company, we have a strong R&D team (located in Hangzhou, Zhejiang, China). We pay great attention to customer feedback. As long as the customer raises a question, we will carefully study and give feedback, and have been studying how to improve the efficiency of our machines. Now we have made the U series. There are few brands in the market that can make such a long-stroke machine and our price must be the most cost-effective, which can give customers more choices and there will be no shortage of supply.

CK650L Wire EDM Machine: Precision and Performance in Complex Cutting

The CK650L Wire EDM machine by 9-Pro is a cutting-edge solution for achieving unmatched precision in electrical discharge machining. Designed to handle complex shapes with superior accuracy, it excels in industries where precise results are critical. From aerospace to precision manufacturing, the CK650L delivers outstanding performance for the most challenging cutting tasks.

Why Choose the CK650L for Precision Cutting?

The CK650L offers exceptional cutting precision, allowing manufacturers to achieve intricate designs and complex geometries. Its advanced electrical discharge machining technology ensures smooth, clean cuts with minimal tolerances, perfect for high-accuracy requirements. The machine’s user-friendly interface enhances operator control, reducing errors and boosting productivity. Built to last, the CK650L also delivers efficiency in processing times, saving costs while maintaining the highest quality output.

With its robust construction and cutting-edge technology, the CK650L is an essential tool for industries where precision is key. Whether in the automotive sector, aerospace engineering, or any other field requiring meticulous cutting, this machine ensures reliability and superior results.

Product Advantages

High-Precision Cutting: The CK650L is designed for high-precision machining, making it suitable for industries requiring intricate and complex cuts, such as aerospace, automotive, and electronics.

Advanced EDM Technology: Utilizing electrical discharge machining technology, the CK650L achieves smooth, burr-free cuts even in hard materials like titanium and alloys. It is known for its high-quality surface finishes.

AWT System Integration: The Automatic Wire Threading (AWT) system enables seamless wire threading during cutting operations, increasing efficiency and reducing downtime.

User-Friendly Interface: Operators can control the machine with ease through an intuitive interface, allowing for precise adjustments and improving operational productivity.

Durable Construction: Built with high-quality materials, the CK650L ensures long-term reliability and performance, even under demanding machining conditions.

Energy Efficiency: The machine is designed for reduced energy consumption, lowering operating costs while maintaining top-tier performance.

Consistent Accuracy: With its cutting-edge controller and precision mechanics, the CK650L guarantees consistent accuracy across multiple runs, making it a dependable option for high-volume production environments.

Corporate Advantages

Commitment: 9-PRO demonstrates a strong commitment to quality and customer satisfaction, focusing on providing high-quality EDM wires and machine parts tailored to precise machining needs.

Capability: The company showcases its capabilities in producing a wide range of EDM products and parts, indicating a robust manufacturing and supply operation aimed at meeting diverse and specific industry requirements.

For more detailed information, please visit 9-PRO's website.

About US

Nestled in the vibrant coastal area of Zhejiang Province, 9-PRO stands as a testament to innovation and dedication in the field of EDM wire manufacturing.

With over eight years of experience, the company weaves a story of precision, passion, and performance. It's not just about the 4000 tons of annual production capacity or the distribution of 200 tons of EDM wire each month; it's about the relentless pursuit of excellence and the commitment to pushing the boundaries of what's possible in EDM technology. This narrative is not just their history; it's a promise to their customers and a vision for the future.

For more about their journey and ethos, visit 9-PRO's Company Page.

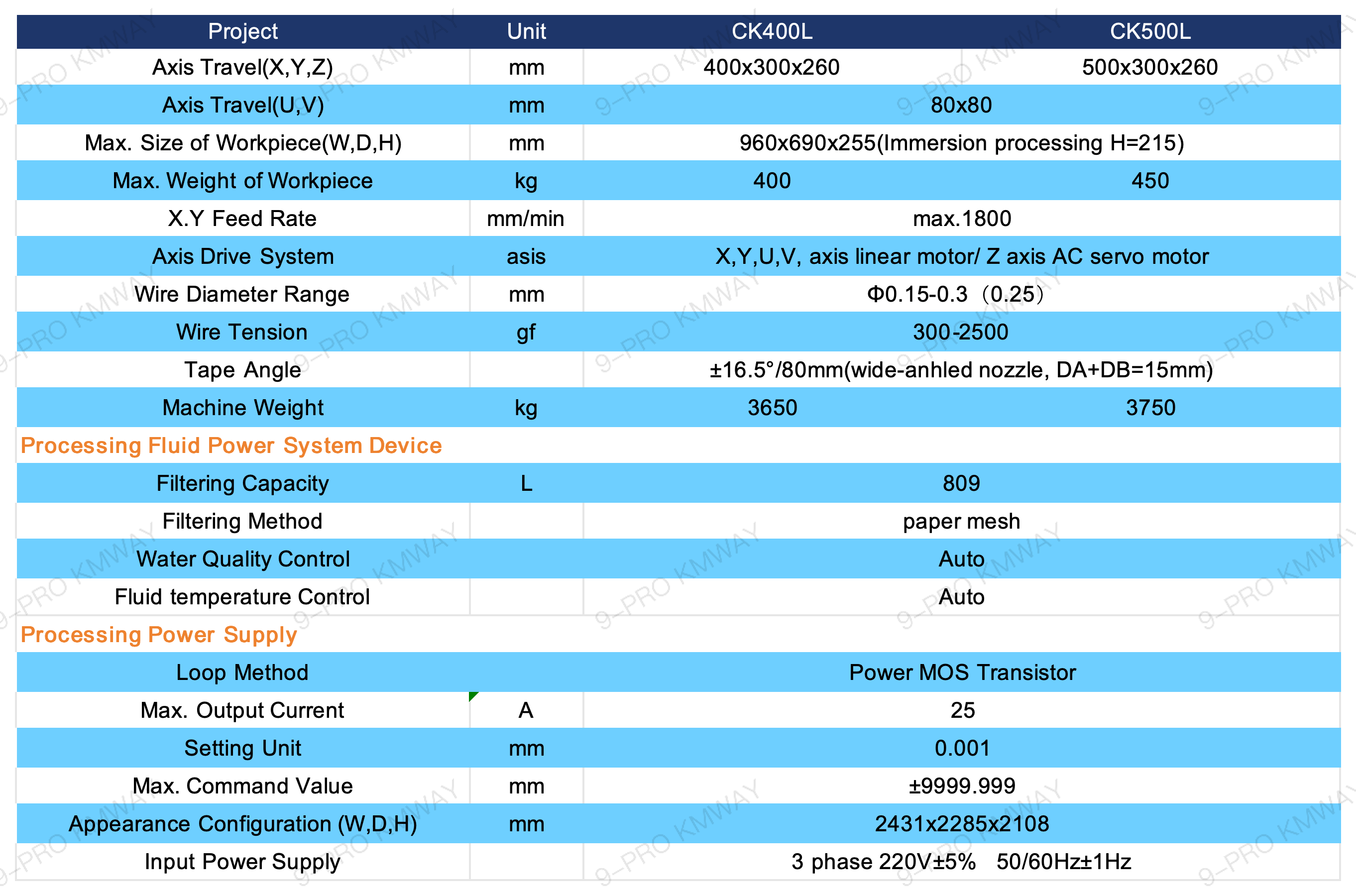

CK400L / CK500L

CK series comes standard with AWT system.

1. Kmway machines combine the advantages of Taiwanese machines and Japanese machines, mainly in synchronization with Chmer's eighth-generation discharge controller, with consistent finish, precision, and efficiency; the AWT system has learned the advantages of Japanese machines and has been updated to the third generation, with a conservative success rate of 95%; including our 3 vertical motors, which are safer and more efficient, less prone to breakdown, and lower maintenance costs.

2. Our service and after-sales team, our technicians can help customers answer questions online at any time. Although the normal working hours are from 8 am to 8 pm China time, when customers really have problems, no matter what time it is, we will try our best to help customers solve them quickly. Including our after-sales team, during dealer training, our after-sales engineers will list the problems and solutions that customers often encounter during use based on their rich experience to help dealers improve the quality of after-sales service.

3. Although Kmway is a new company, we have a strong R&D team (located in Hangzhou, Zhejiang, China). We pay great attention to customer feedback. As long as the customer raises a question, we will carefully study and give feedback, and we have been studying how to improve the efficiency of our machines. Now we have made the U series. There are few brands in the market that can make such a long-stroke machine and our price must be the most cost-effective, which can give customers more choices and there will be no shortage of supply.

Leading Precision in Wire EDM Technology

Unleash the full potential of your production with the CK400L/500L Series, integrating state-of-the-art technology for unmatched accuracy and speed in wire cutting.

Designed for the Industry's Best

These machines embody robust design and advanced control systems, offering exceptional functionality tailored for high-stake industries like aerospace and automotive manufacturing.

The CK400L/500L series from 9-Pro provides significant advantages for high-efficiency wire electrical discharge machining (WEDM):

Advanced AWT System: Features a third-generation Automatic Wire Threading (AWT) system with a high success rate of 95%, enhancing reliability and reducing downtime.

Superior Control Technology: Integrates with Chmer's eighth-generation discharge controller for consistent high finish, precision, and efficiency, matching the performance of top-tier machines.

Durable and Safe Design: Equipped with three vertical motors that ensure safer, more efficient operations and lower maintenance costs.

Robust After-Sales Support: This includes a dedicated service team available for online support outside of normal working hours to quickly resolve any issues and ensure continuous operation.

Corporate Advantages

Commitment: 9-PRO demonstrates a strong commitment to quality and customer satisfaction, focusing on providing high-quality EDM wires and machine parts tailored to precise machining needs.

Capability: The company showcases its capabilities in producing a wide range of EDM products and parts, indicating a robust manufacturing and supply operation aimed at meeting diverse and specific industry requirements.

For more detailed information, please visit 9-PRO's website.

About US

Nestled in the vibrant coastal area of Zhejiang Province, 9-PRO stands as a testament to innovation and dedication in the field of EDM wire manufacturing.

With over eight years of experience, the company weaves a story of precision, passion, and performance. It's not just about the 4000 tons of annual production capacity or the distribution of 200 tons of EDM wire each month; it's about the relentless pursuit of excellence and the commitment to pushing the boundaries of what's possible in EDM technology. This narrative is not just their history; it's a promise to their customers and a vision for the future.

For more about their journey and ethos, visit 9-PRO's Company Page.

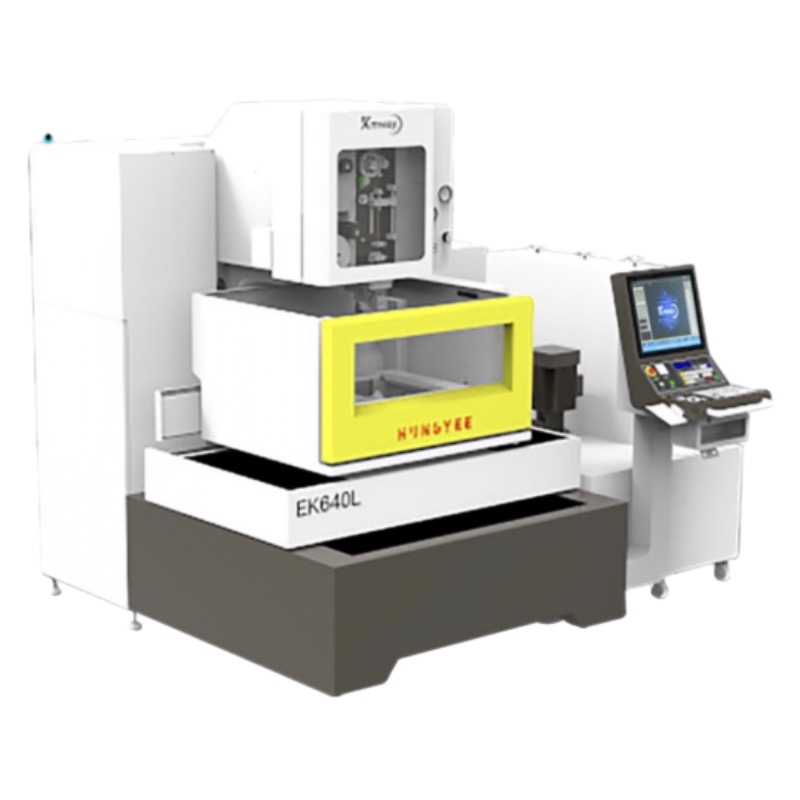

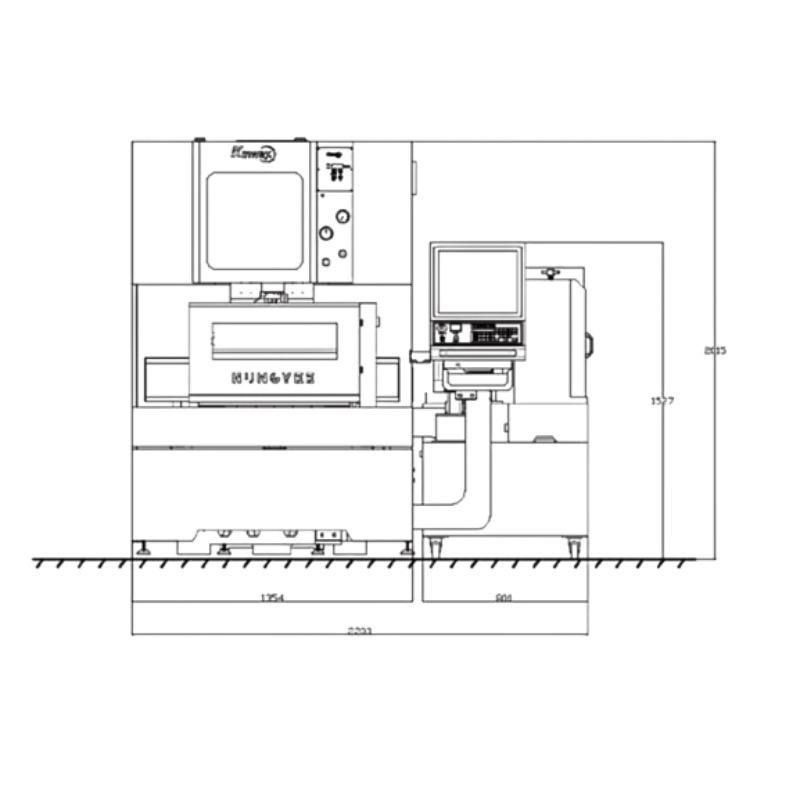

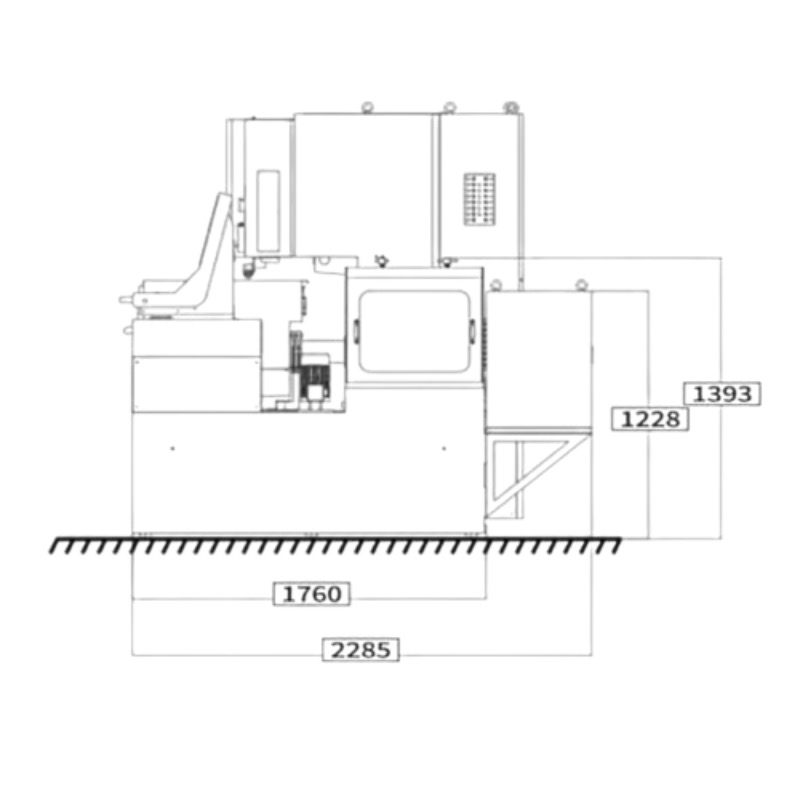

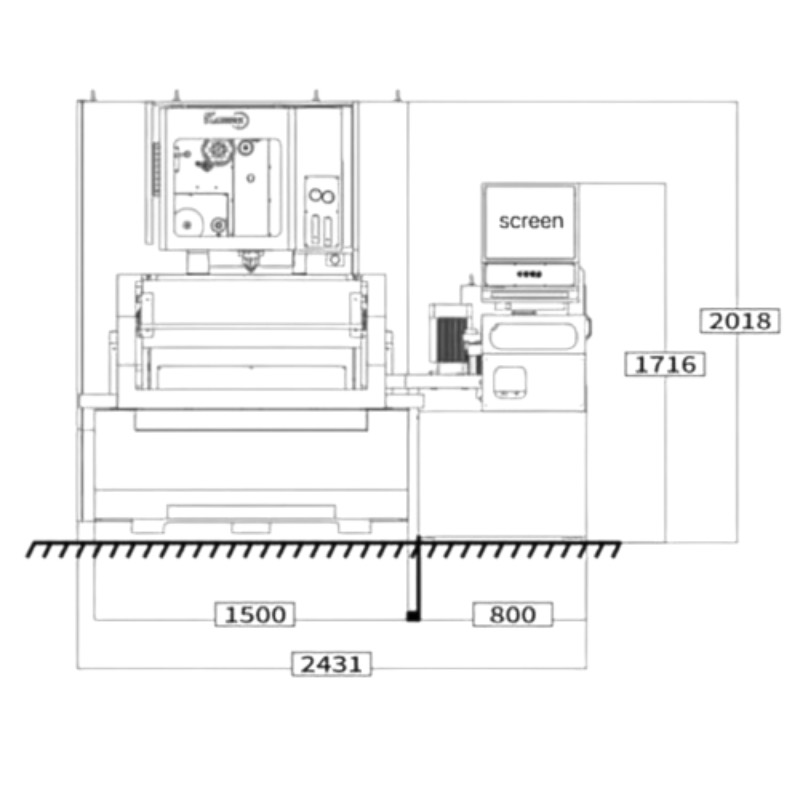

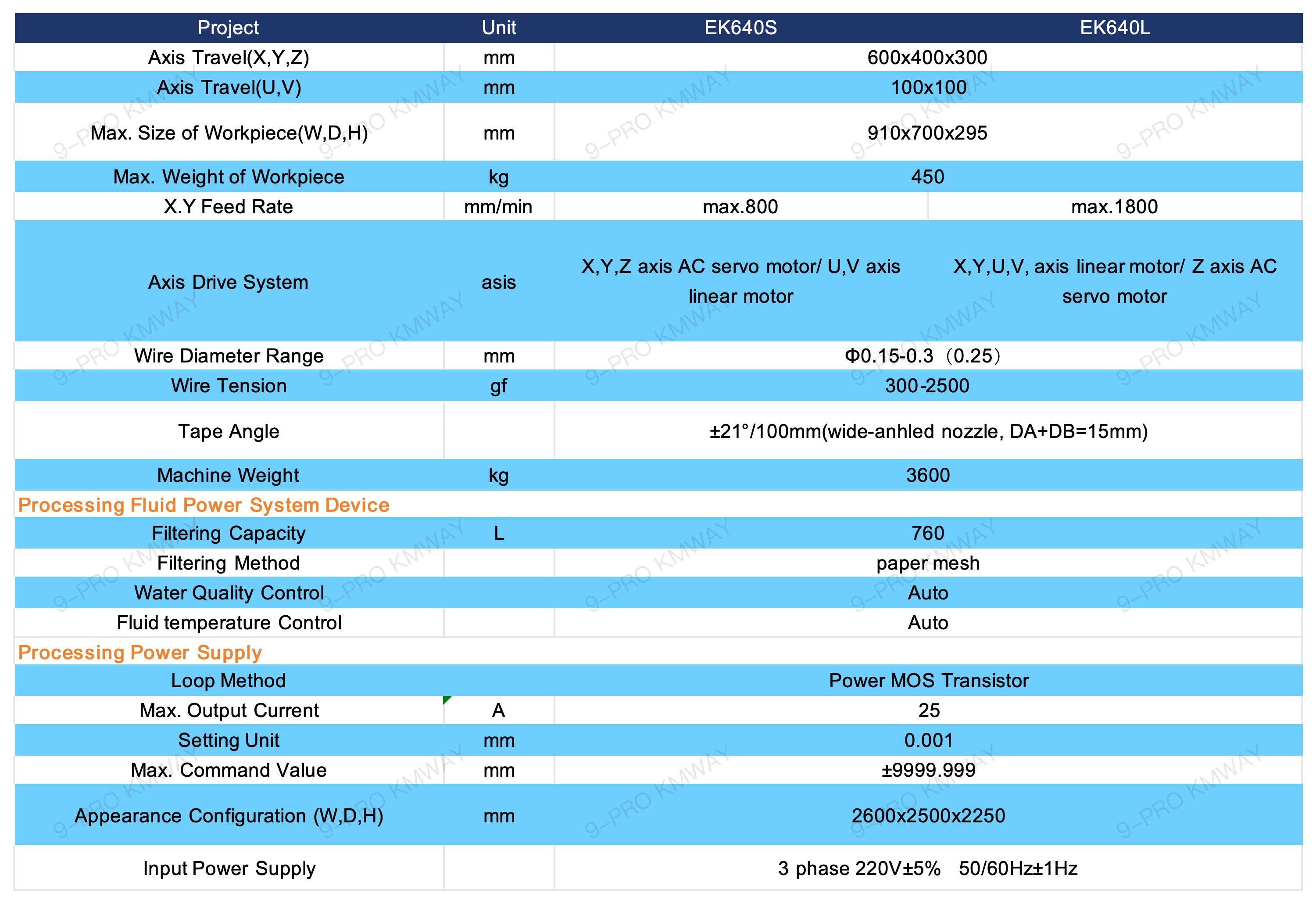

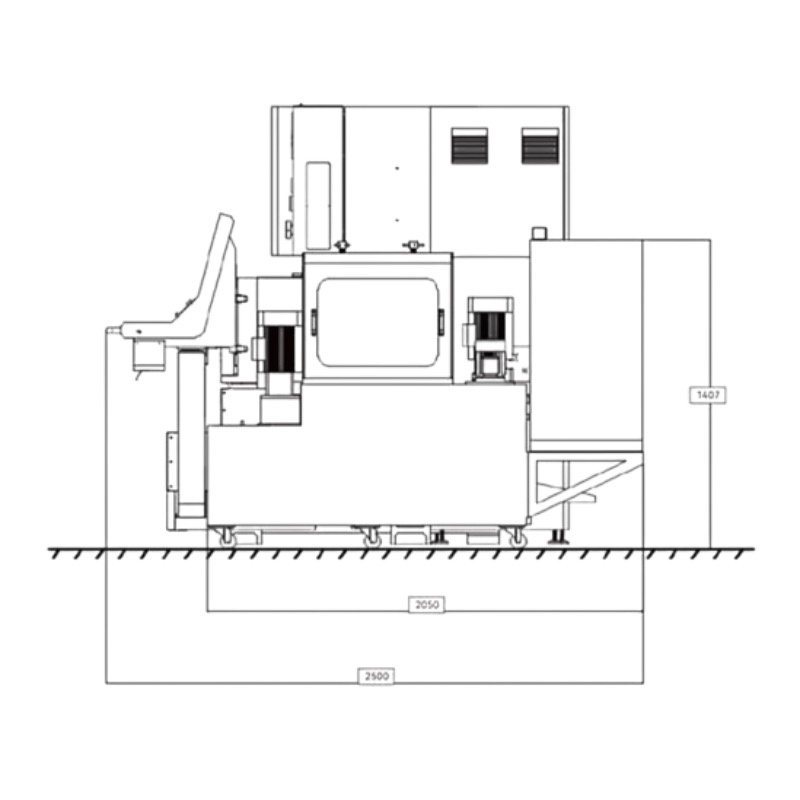

EK640S / EK640L

It should be noted that the AWT system of this model needs to be selected, and we will charge a reasonable price.

1. Kmway machines combine the advantages of Taiwanese machines and Japanese machines, mainly in synchronization with Chmer's eighth-generation discharge controller, with consistent finish, precision, and efficiency; the AWT system has learned the advantages of Japanese machines and has been updated to the third generation, with a conservative success rate of 95%; including our 3 vertical motors, which are safer and more efficient, less prone to breakdown, and lower maintenance costs.

2. Our service and after-sales team, our technicians can help customers answer questions online at any time. Although the normal working hours are from 8 am to 8 pm China time, when customers really have problems, no matter what time it is, we will try our best to help customers solve them quickly. Including our after-sales team, during dealer training, our after-sales engineers will list the problems and solutions that customers often encounter during use based on their rich experience to help dealers improve the quality of after-sales service.

3. Although Kmway is a new company, we have a strong R&D team (located in Hangzhou, Zhejiang, China). We pay great attention to customer feedback. As long as the customer raises a question, we will carefully study and give feedback, and we have been studying how to improve the efficiency of our machines. Now we have made the U series. There are few brands in the market that can make such a long-stroke machine and our price must be the most cost-effective, which can give customers more choices and there will be no shortage of supply.

Advanced Precision with 9-Pro WEDM Machines

Experience cutting-edge technology with the 9-Pro EK Series WEDM machines, offering high precision wire cuts for complex and detailed metal work. Ideal for industries requiring exacting standards.

Key Features of the EK640S/L Series

These WEDM machines feature robust construction, precision control systems, and are equipped with state-of-the-art technology to ensure efficient and accurate machining. Perfect for both small and large-scale operations.

The EK640S/L series from 9-Pro offers several compelling advantages for precision wire cutting:

Advanced Control System: Integrates Chmer's eighth-generation discharge controller, ensuring high finish, precision, and efficiency consistent with top industry standards.

Enhanced AWT System: Features an updated third-generation Automatic Wire Threading (AWT) system with a high success rate of 95%, making it reliable and efficient for complex jobs.

Robust Construction: Includes three vertical motors that enhance the machine's operational safety and efficiency while reducing breakdowns and maintenance costs.

Comprehensive Support: Offers strong after-sales support where technicians are available online to resolve issues promptly, ensuring minimal downtime and maintaining high productivity.

Corporate Advantages

Commitment: 9-PRO demonstrates a strong commitment to quality and customer satisfaction, focusing on providing high-quality EDM wires and machine parts tailored to precise machining needs.

Capability: The company showcases its capabilities in producing a wide range of EDM products and parts, indicating a robust manufacturing and supply operation aimed at meeting diverse and specific industry requirements.

For more detailed information, please visit 9-PRO's website.

About US

Nestled in the vibrant coastal area of Zhejiang Province, 9-PRO stands as a testament to innovation and dedication in the field of EDM wire manufacturing.

With over eight years of experience, the company weaves a story of precision, passion, and performance. It's not just about the 4000 tons of annual production capacity or the distribution of 200 tons of EDM wire each month; it's about the relentless pursuit of excellence and the commitment to pushing the boundaries of what's possible in EDM technology. This narrative is not just their history; it's a promise to their customers and a vision for the future.

For more about their journey and ethos, visit 9-PRO's Company Page.

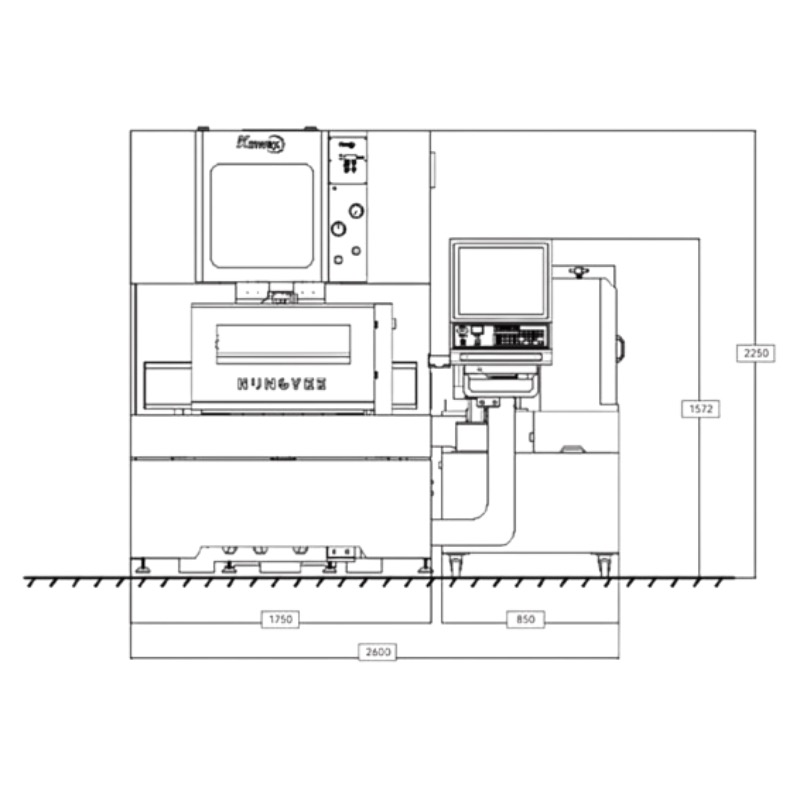

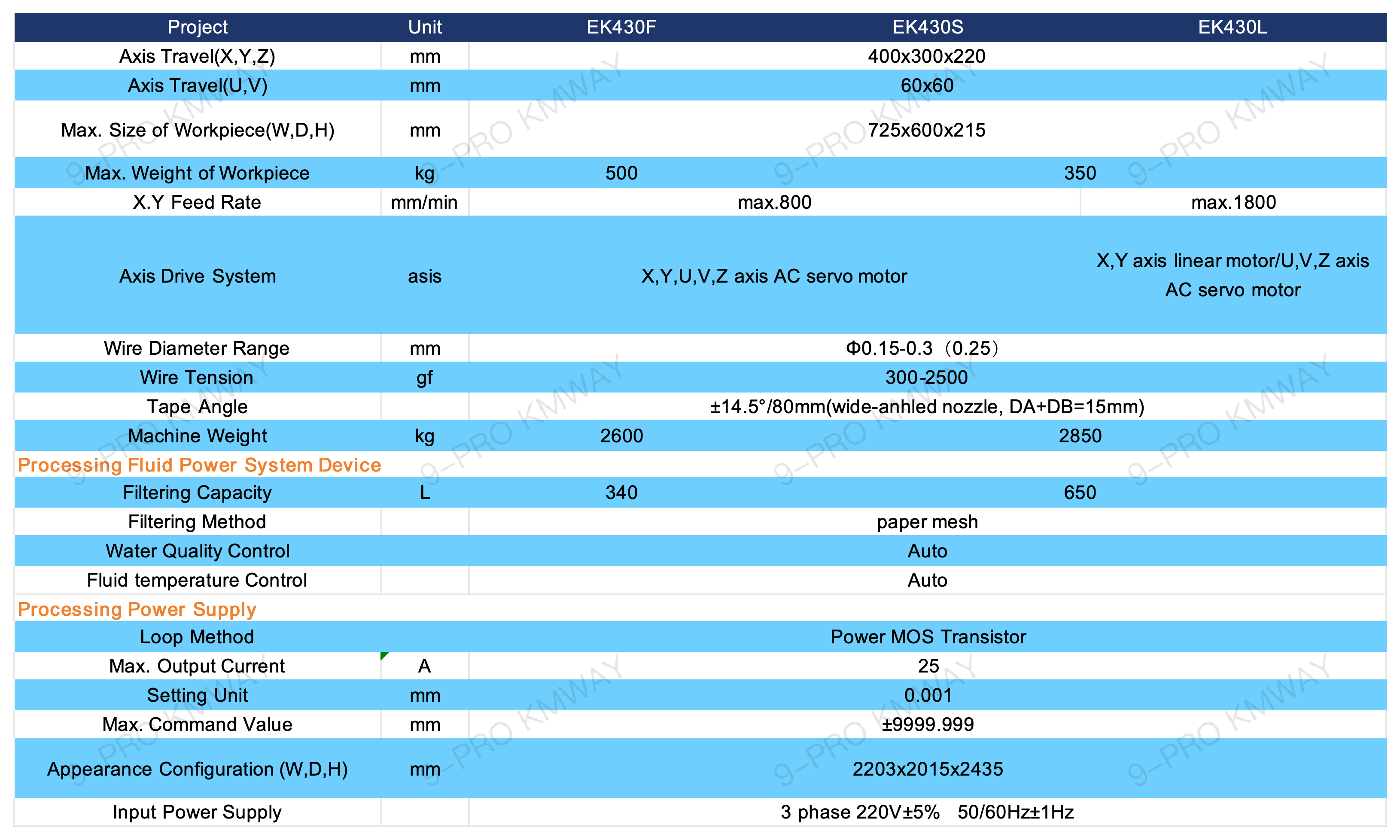

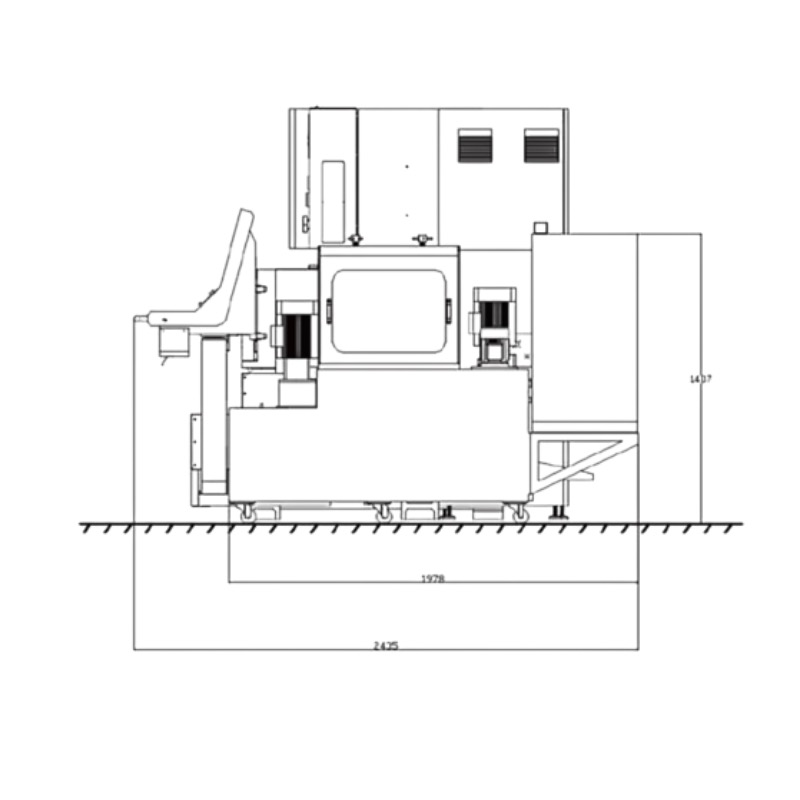

Kmway EK Series Advanced WEDM Machines | Precision Wire Cutting Technology | EK430F/ EK430S/ EK430L

1. Kmway machines combine the advantages of Taiwanese machines and Japanese machines, mainly in synchronization with Chmer's eighth-generation discharge controller, with consistent finish, precision, and efficiency; the AWT system has learned the advantages of Japanese machines and has been updated to the third generation, with a conservative success rate of 95%; including our 3 vertical motors, which are safer and more efficient, less prone to breakdown, and lower maintenance costs.

2. Our service and after-sales team, our technicians can help customers answer questions online at any time. Although the normal working hours are from 8 am to 8 pm China time, when customers really have problems, no matter what time it is, we will try our best to help customers solve them quickly. Including our after-sales team, during dealer training, our after-sales engineers will list the problems and solutions that customers often encounter during use based on their rich experience to help dealers improve the quality of after-sales service.

3. Although Kmway is a new company, we have a strong R&D team (located in Hangzhou, Zhejiang, China). We pay great attention to customer feedback. As long as the customer raises a question, we will carefully study and give feedback, and we have been studying how to improve the efficiency of our machines. Now we have made the U series. There are few brands in the market that can make such a long-stroke machine and our price must be the most cost-effective, which can give customers more choices and there will be no shortage of supply.

It should be noted that the AWT system of this model needs to be selected, and we will charge a reasonable price.

Note: EK430F cannot select AWT system, EK430S and EK430L can select AWT system, thank you!

1. Kmway uses three vertical water tanks, which contain solenoid valve signal control. It is not like the traditional water tank that starts as soon as water is added, which is more energy-saving.

2. Kmway's air cooler is Gree variable frequency, which is more cost-effective and more energy-saving.

3. Kmway's machines are all integrated, which is more convenient for customers to operate and avoids the trouble of pulling the wires back and forth during work.

4. Kmway provides a one-year extended warranty service for circuit boards for new customers in the region, with a total of two years of warranty.

5. Kmway's automatic threading success rate is higher, and the maintenance of the machine is not as frequent as that of Taiwan's machines, which also saves costs in the later use process.

Advanced Wire WEDM Solutions

The Kmway EK430 Series WEDM Machines integrate the latest technological advancements from Taiwanese and Japanese engineering, ensuring unparalleled precision and efficiency in electrical discharge machining.

Robust Design and Features

Equipped with Chmer's eighth-generation discharge controller and an optional AWT system, the EK430 series promises consistent finishes and operational excellence.

Commitment to Innovation and Quality

Backed by a dedicated R&D team and robust after-sales support, Kmway's EK430 series is engineered to meet the rigorous demands of modern manufacturing environments.

Product Advantages

Advanced Control Technology: Incorporates Chmer's eighth-generation discharge controller, ensuring consistent finish, precision, and efficiency.

Enhanced AWT System: Features a third-generation AWT system with a high success rate, improving reliability and performance.

Robust Construction: Includes three vertical motors that offer safety, efficiency, and reduced maintenance costs.

Responsive After-Sales Support: Provides comprehensive dealer training and 24/7 customer support.

Versatile Machining Capabilities: Supports a wide range of wire diameters and has an efficient wire feed rate, suitable for various cutting needs.

Corporate Advantages

Commitment: 9-PRO demonstrates a strong commitment to quality and customer satisfaction, focusing on providing high-quality EDM wires and machine parts tailored to precise machining needs.

Capability: The company showcases its capabilities in producing a wide range of EDM products and parts, indicating a robust manufacturing and supply operation aimed at meeting diverse and specific industry requirements.

For more detailed information, please visit 9-PRO's website.

About US

Nestled in the vibrant coastal area of Zhejiang Province, 9-PRO stands as a testament to innovation and dedication in the field of EDM wire manufacturing.

With over eight years of experience, the company weaves a story of precision, passion, and performance. It's not just about the 4000 tons of annual production capacity or the distribution of 200 tons of EDM wire each month; it's about the relentless pursuit of excellence and the commitment to pushing the boundaries of what's possible in EDM technology. This narrative is not just their history; it's a promise to their customers and a vision for the future.

For more about their journey and ethos, visit 9-PRO's Company Page.