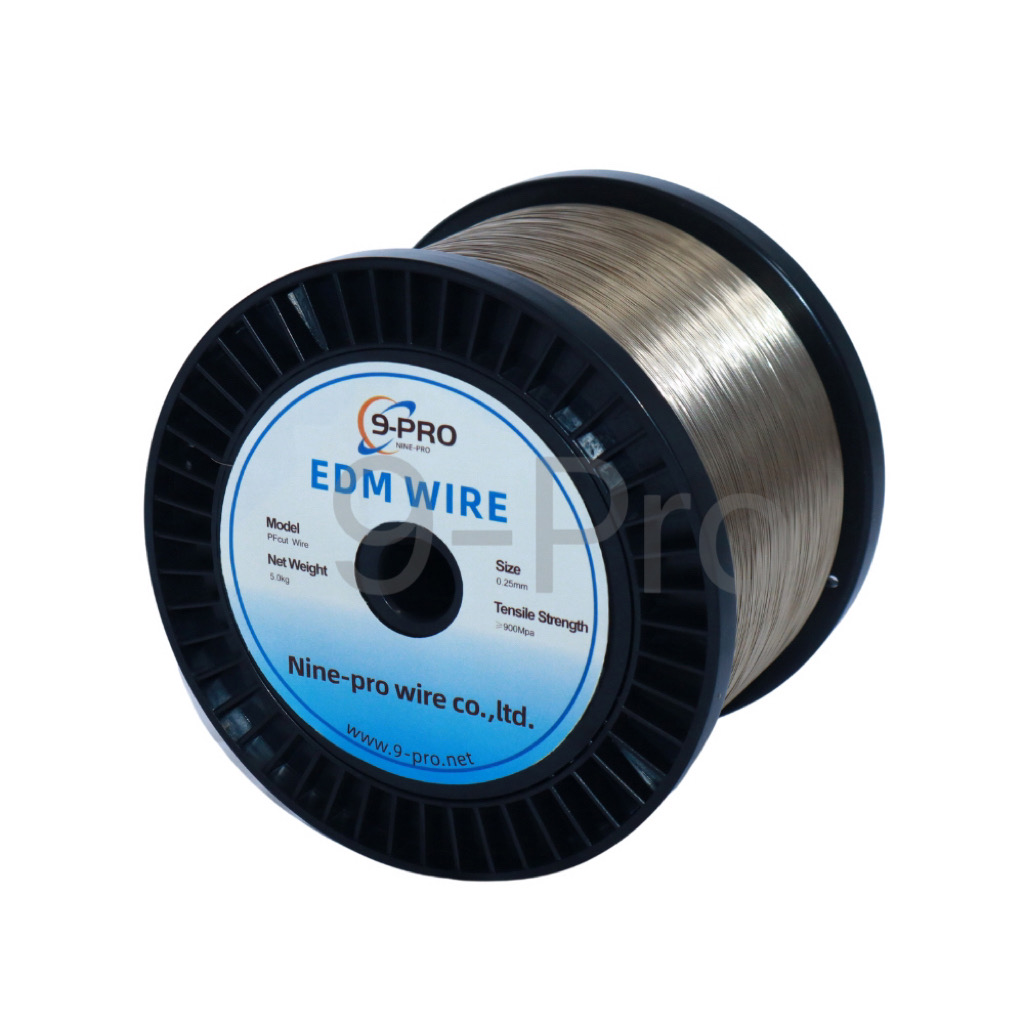

In the fast-paced world of machining, precision and efficiency are not just desirable—they are essential. Enter the BScut EDM wires from 9-Pro, a game-changer in this field. These wires are crafted to surpass traditional solutions, offering enhancements that could significantly optimize your machining processes.

Table of content

Understanding the Composition of BScut EDM Wires for Superior Results

The Role of BScut Wires in Achieving Fine Surface Finishes

Comparing BScut EDM Wires to Traditional EDM Wire Solutions

This blog will walk you through the technology behind these innovative wires, from their superior composition to their applications across various machining tasks, particularly for those using AgieCharmilles machines. Explore how BScut wires can transform your machining with unparalleled precision and speed.

Understanding the Composition of BScut EDM Wires for Superior Results

The superior performance of BScut EDM wires is rooted in their unique composition. Made with CuZn37, these wires feature a γ phase coating that significantly enhances their cutting capabilities. The combination of copper and zinc improves thermal conductivity and tensile strength, allowing for smoother operations and finer finishes. This specific blend also supports increased cutting speeds, reducing the time required for machining tasks without compromising accuracy. It's the meticulous design and material choice that position BScut wires at the forefront of machining technology. What truly sets BScut wires apart from traditional options is their clean-burning capability, which minimizes residue build-up and prolongs the life of EDM consumables like filters and guides. This contributes to cost-effectiveness over time, making BScut wires an ideal choice for businesses looking to streamline operations while maintaining high standards of quality. Additionally, the automatic threading feature ensures seamless integration into existing machining processes, saving valuable time and reducing manual intervention.

The Role of BScut Wires in Achieving Fine Surface Finishes

Achieving fine surface finishes is crucial in many industries, from aerospace to automotive manufacturing. BScut wires are engineered to meet these high demands with exceptional precision. Their advanced composition allows for smoother cuts, resulting in a surface finish that often requires little to no additional polishing. This capability can significantly reduce the total manufacturing time and improve output quality, providing a direct advantage in terms of customer satisfaction and operational efficiency. The ability to produce such refined finishes is due largely to the BScut wire’s unique γ phase coating, which enhances the wire's stability during high-speed operations. This stability minimizes vibration and deviation, key factors in maintaining consistent surface integrity throughout the machining process. By using BScut wires, manufacturers can ensure that every component meets stringent quality standards, bolstering their reputation for excellence.

Comparing BScut EDM Wires to Traditional EDM Wire Solutions

When stacked against traditional EDM wires, BScut wires offer a number of advantages that make them a preferred choice for many manufacturers. Traditional wires, often made from pure brass or soft copper, typically do not offer the same level of speed or precision. In contrast, BScut wires are specially formulated to optimize performance, offering faster cutting speeds and cleaner burning, which leads to less maintenance and downtime. One of the most significant disparities lies in the cutting precision achievable by each type of wire. BScut wires, with their advanced γ phase coating and optimized material composition, allow for tighter tolerances and more intricate designs. This is particularly beneficial for industries that demand high precision, such as medical device manufacturing or microelectronics. Traditional EDM wires, by contrast, may struggle to maintain such high levels of precision, particularly over long production runs.

In a world where precision and efficiency are paramount, the technology behind BScut EDM wires offers revolutionary potential for the machining industry. With their unique composition of CuZn37 and γ phase coating, these wires deliver cutting speeds and surface finishes that set new standards. Their comparison to traditional EDM wires highlights significant gains in speed, precision, and cost-effectiveness, making them an optimal choice for modern manufacturers. Whether you're a small machine shop or a large manufacturing enterprise, incorporating BScut wires into your processes can provide a competitive edge. To explore these benefits further and see how BScut wires can specifically enhance your operations, consider reaching out to 9-Pro for expert guidance. Their team can tailor solutions to meet your specific needs, ensuring that you achieve the best possible outcomes from your machining efforts.